Drive in Pallet Racking

Key benefits

- Huge amount of storage capacity

- Very space efficient design

- Can handle large around of weight per pallet

- Huge variety in construction layout, on X,Y,Z axis.

- Number of pallets deep

- Number of pallets wide

- Number of pallets high

Drive in Pallet Racking

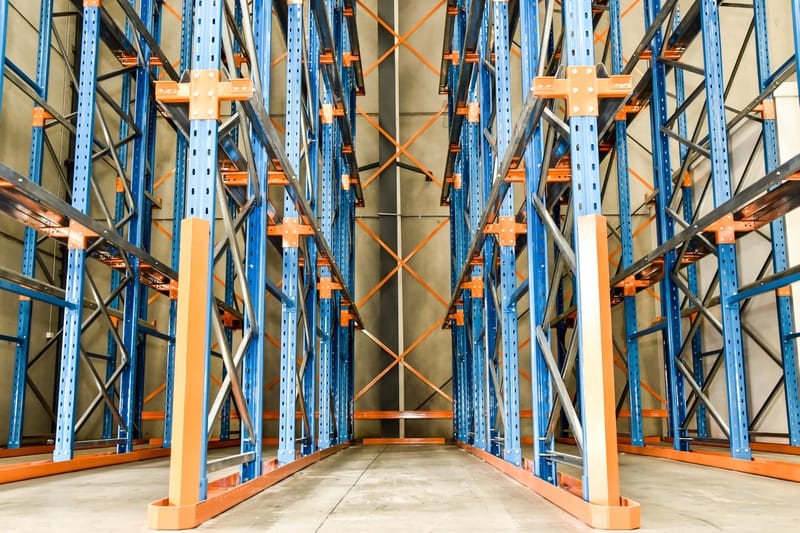

Maximise your pallet storage capacity with drive in racking. Cramped for space and need to store large quantities of pallets in your warehouse. Then drive in Racking is the solution for you. Utilise all of your warehouse space with the BOS Drive in racking system designed specifically to maximise the most amount of pallet stored with the smallest footprint.

Increase Storage Capacity

How can I store more pallets in my warehouse?

As one of the most space saving pallet storage systems, drive in racking allows you to store huge amounts of pallets in a relatively small footprint. Compared to regular pallet racking, you can almost double the storage capacity in the same warehouse. So if you are in need to store more pallets then what your current warehouse can carry, turn to drive in pallet racking as a great option.

How drive in racking works

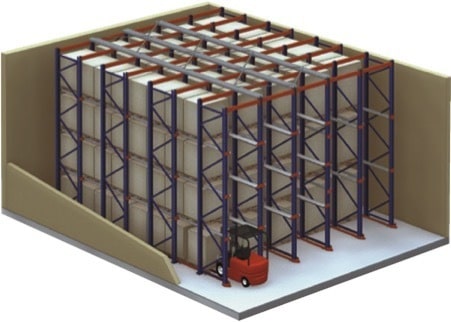

The racking components form inner loading lanes with support rails on each side for the pallets. The forklift drives into the lanes and stacks the goods onto the rails, all the way until the end, thereby utilising the full depth of the installation. The rack itself is made of a robust material, making it durable and fit to handle fully loaded pallets. If placed against a wall, it works according to the FILO (first in, last out) principle.

Drive in Versatility

Bulk pallet storage ideas. What’s best warehouse storage solution for space saving? Drive-in pallet racking by BOS Storage Systems. With a multi level, multi depth, multi width storage concept, you can store more pallets in the same area as normal racking, because we eliminate the need to have so many forklift aisles. Less aisles means more pallets! Before you ask, you more than likely can use your existing forklift as well. What do you have to loose? Or gain? Call BOS Storage for a free design and chat about the design and what it can do for you.

Applicable Industries

-Food Producers – Food manufacturers – IBC Storage – Bulkabag storage – Packaging – Chemical Storage – Logistics – Meat works – Cold room Storage

Design Features

- Based off a 76.2mm pitch upright you can set the pallet rails at numerous heights up the racking system depending on your pallet height and the configuration that works best for you warehouse

- Bays are 1350mm wide between uprights which is ample room for both pallet and forklift to travel down the lane

- Pallet rails are 132mm x 129mm steel angle 1.8mm thick. This accommodates pallets upto 1000kg each. These run the full depth of the drive in rack, preventing the pallets from snagging on any stop start joints

- Floor channels can also be included which are 135mm x 80mm channel that runs the full depth of the rack 8mm thick to prevent the forklift from steering into the racking system and also guiding the ground level pallet

- Frames are 1250mm deep with 1250mm gaps between frames allowing ample room for the pallets to sit in stacked front to back

- The drive in system is uniquely braced over the top (which is called portal bracing), to increase the rigidity of the structure. This gives the racking system exceptional performance and longevity.

Drive in possibilities

Depending on your storage requirements and warehouse space, we customise a drive in rack to suit your specific needs. The system allows for flexibility. Pallet height, number of pallets deep, number of pallets high, number of pallets wide.

You can also adjust each land to be different. If you have a building column behind a lane of drive in rack, you can make this single lane shallower by 1 pallet. If you have roof rafters in the way, we can step the top height down in the lane. Same if you want to adjust the number of pallet levels in each bay and vary in each lane.

Inclusions

- Levelling plates

- Floor Fixings

- Bracing and hardware

- Safe Work Load Signs (to comply with Australian Standards).

Optional Extras

- Rack protection

- Floor Channel

- Rated over 1000kg per pallet

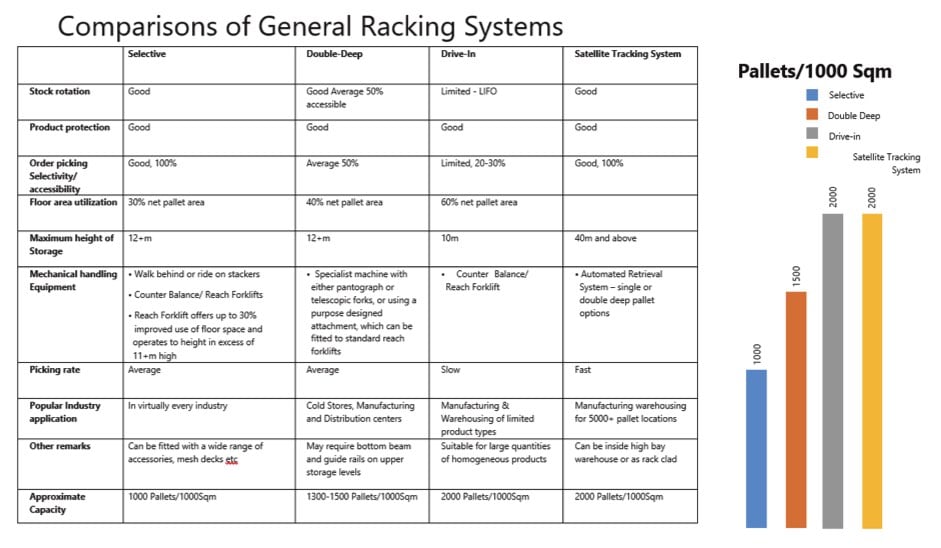

Comparisons

What is Drive in Racking

Drive in racking is a static system which allows forklift drivers to load the system back to front. Also stacking pallets in front of one another on elevated rails. Essentially the system has a number of horizontal rails the run front to back down each ‘lane’. We bolt the rails to the uprights, which only stick out far enough to catch the sides on the pallets. We then have a number vertical levels of rails going up the system to create levels of storage.

So a pallet can be take up to a certain level, driven down the lane by the forklift and placed on the rails. This storage system allows you to store many levels of pallets, many pallets deep. A benefit is that the front pallet on each level is accessible without having to take all the pallets above off. This of course increases accessibility to your stock.

Additionally, unlike ‘block stacking’ (stacking pallets on top of each other), pallets are not squashed. Because they are not stacked, they occupy their own level.

Drive in racking is a fantastic solution for storing same SKU pallets. This is because it keeps product in the same location / pick face. Thus eliminating issues with lost or misplaced product.

Drive in racking also one of the best solutions for warehouse storage efficiency. You can store a huge amount of pallets in a single area with drive in racking. Simply because you are storing in 3 planes, height, depth, width. It creates a ‘block’ of sorts where the product uses the majority of the space and storage area isn’t taken up by forklift aisles.