Double Deep Racking

Key benefits

- Can store more pallets in the same size warehouse compared to regular pallet racking.

- Reduces the amount of aisles needed in the warehouse

- Pantographic Forklift extends its tines to reach front and rear pallets

- Works best with pallets of same product

- Works with regular Australian pallets

- Same price as regular pallet racking

- Increased storage capacity

- Economical Solution. Cheap alternative

- Use existing racking to form double deep system

Double Deep Racking

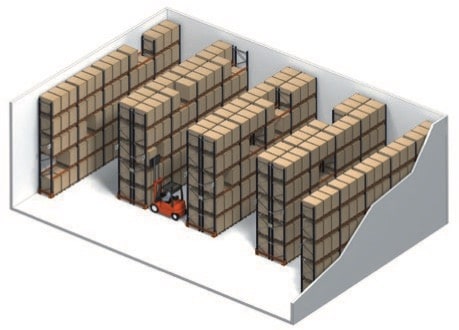

Do you need to store more pallets in your warehouse? Double Deep Racking is an innovative and cost effective way to do so. With minimal expenditure, you essentially double the storage capacity of your current racking. Get more capacity from your existing racking set up with a 2 deep style racking system. It’s great for industries with uniform or many pallets of the same goods. Customisable to suit your warehouse and your product.

Employs ‘Last in First Out’ (LIFO) principle with a 50% selective rate.

How Double Deep Racking Works

Double deep pallet racking is often referred to as deep store racking or 2 deep racking. Its works off the idea that the special reach forklift can access a pallet in the front position, but also extend its tines out to reach a pallet behind the front pallet. Exploiting the idea, you can utilise this function, essentially creating normal pallet racking, but 2 pallets deep.

Therefore, you can have 2 deep racking ‘back to back’ which allows you to store 4 pallets deep, and access 2 pallets from either side of the rack. This cuts down on the amount of aisles needed in the warehouse resulting on more storage capacity in the area.

Space Saving Rack Configuration

When trying to maximise your warehouse storage capacity, double deep racking is a really smart and cost effective way to do so. By having a forklift that can access 2 pallets deep you allow yourself to essentially double the amount pallets within a warehouse. How, you ask? Pallet racking and warehouse storage is all about optimising space, and aisles between pallet racks is a big use of space. So reducing the amount of aisles in your warehouse, instantly increases the usable space.

Double deep racking is very effective at storing same or similar goods. If your have numerous pallets of the same goods, then double deep racking should be on your radar.

Alternative to Drive in Racking

Is there an alternative to Drive-In racking? Is there an cheaper option for Drive-in racking? Maybe 2 deep racking would be a better alternative. This very economical form of pallet storage allows you to store 2 pallets deep, using standard pallet racking. You can even convert your existing pallet racking to this system! Double deep racking (sometimes referred to as ‘Deep Store’), uses normal pallet racking, 1 row in front of another… but with a smaller gap between the pallets. So your pantographic forklift and extend out and grab 2 pallets from the 1 location.

The system is adjustable to any form of levels and heights, as well as layout and total capacity.

Applicable Industries include;

– Food production – Packaging – Raw material – Manufacturing – Bulkabag – IBC Storage – Liquid Storage – Chemicals Storage

Design Features

- Same racking system as regular pallet racking

- 76.2mm pitched frames

- 1000kg per pallet, or higher if required

- 2591mm wide beams or 2743mm wide beams if required

- Double pallet wide beams as well as single pallet wide

- Height and number of beam levels is determined by your forklift and warehouse.

Inclusions

- Levelling plates

- Floor Fixings

- Bracing and hardware

- Safe Work Load Signs (to comply with Australian Standards)

Optional Extras

- Pallet guides

- Rack protection

- Wider beams for straddle trucks