Racking Audit

Key Reasons for Audit

The main reason for a pallet racking audit is to assess the structural integrity of your pallet racking and make sure that it is safe to use and wont cause injury to any staff do to failure.

What a pallet racking auditor is looking for:

- Damage to the racking;

- Frames

- Beams

- Safety clips

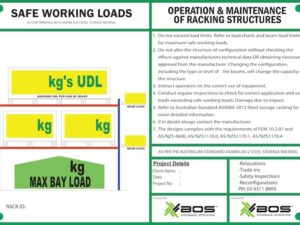

- SWL (Safe Work Load Signs)

- Floor fixings

- Rust

- Racks not plumb or level

- If there is different types of racking mixed together

- Assess the structural integrity of the racks

- Ensure that the racks are not being overloaded

- Ensure that the racks are being used correctly

The Australian Standards on pallet racking AS4084 recommend that you have your pallet racking inspected on a 12 month basis by someone who is competent. So as a business owner or warehouse manager you have a responsibility to ensure this is carried out.

Racking Audit

Perform an Australian Pallet Racking audit annually to ensure the safety of your staff and your product. Under the Australian standards (AS 4084-2012) you should have your racking audited every 12 months to ensure that everything is safe and in usable order. Failing to do this might result in rack failure or collapse and be devastating your your staff and your business. Call BOS Storage now to get a Pallet rack Safety audit in your warehouse and fix any damage.

Repair or replacement of Damaged racking components is urgent as well as paramount. Ultimately this eliminates possible accidents, some of which could be very expensive.

Therefore it is crucial that Safety signage installation, including Safe Working Load (SWL) signage occurs. Most important, this is in accordance with Australian Standards and FEM requirements.

Pallet Rack Inspection

BOS Storage has Rack Auditors Nation wide to provide this service to ensure that your Pallet racking is in proper working order, but carrying out a rack audit and providing a report of the current state of the racks, and providing a quote to fix any damage or rectifications.

Audits are often referred to as;

– Pallet racking audit – Warehouse certification – Australian standard rack inspection – Rack inspection – Warehouse storage audit & Rack Audit

WH & S

Workplace Health and Safety with Pallet Racking

Work place health and safety has authority to enforce shut downs in operations if you do not have a safe work environment. So, when it comes to pallet racking, WH&S will be targeting you. An signed inspection of your racks is a requirement every year by a competent professional.

The best way to do this is to have your pallet racks annually audited by a professional rack auditor. Consequently you then carry out any rectification works, or address any non-compliant issues.

Q & A's

What Does a Pallet Rack Audit Entail?

Initiating a racking audit begins with the business owner or warehouse manager contacting a professional racking company. BOS Storage Pty Ltd will then set up a time to conduct the pallet racking audit and come to site. Once on site we will begin a ground based inspection of all the racking within the warehouse. This is essentially a walk around the site and inspecting the racking from ground level.

We do a floor plan of the racking/warehouse layout, which immediately identifies where each defect or flagged item is. As the rack auditor is walking around the warehouse they will list any defects, damage or non compliant issues. Then they note it for the audit report.

On completion (but still onsite), the auditor will inform the warehouse manager / business owner. They will discuss any major defects that are cause for immediate concern. Following the onsite inspection the auditor will create a CAD floor plan. The plan marks where they identify damage, creating an audit report detailing any defects. We send this to the client along with a quote to carry out repairs of the listed defects/ non compliant items. It is then the responsibility of the client to act on these issues.

Do BOS Storage conduct Pallet Racking Audits?

Yes!

BOS Storage conducts pallet racking audits on all warehouses with all brands of racking.

If you need a warehouse audit or a pallet rack audit, Call BOS Storage. You will talk to one of the very helpful technical experts or sales team who will organise an audit for you.

How much does an audit cost?

We have a set admin fee of $450+gst* per warehouse, plus $60+gst per man hour on site.

Audits usually take appprox 1 hour for warehouses under 150 pallet locations. However, this is very dependent on many factors such as;

- How much damage there is

- What condition that racking is in

- If there is a mixture of brands.

Thus we have a base admin fee and will charge additionally if needed.

AS4084

The Australian Standards on Pallet Racking

The Australian Standards on Pallet Racking falls under AS4084 : 2012 Steel Storage Racking.

Under these standards you are required to carry out a pallet racking safety audit every 12 months to ensure that the racking you have is deemed safe and suitable for use. If you do not comply with this then you may void your warranty or worse, have a catastrophic incident or collapse.

It’s a annual safety requirement that will help protect you from work place injury or stock loss.